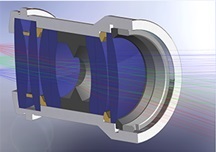

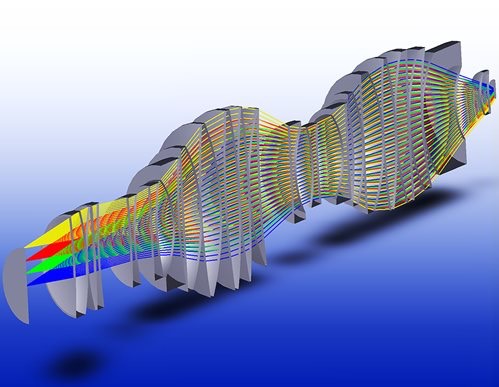

When mechanical engineers send STEP files back to the optical engineer for validation, the optical engineer must deal with the challenges of inconsistent global coordinate systems and lost design fidelity and must manually locate individual mechanical components to recreate the assembly that the mechanical engineer created in SOLIDWORKS. Even subtle changes to the mechanical geometry, or inaccuracies from poor optical data integrity, can significantly impact optical performance. Mechanical engineers also lack a quick or accurate way to check that the mechanical geometry does not impact optical performance. Mechanical engineers rely on optical engineers to validate designs or build costly, time-consuming physical prototypes to identify design problems.Ray bundles are imported as static sketches that represent a very small sample of the actual rays used in the optical analysis and cannot be updated with design changes and.STEP, IGES, or STL files degrade the accuracy of optomechanical designs, and optical tolerances, coating types, and material data are lost during file conversion.This technique often introduces inaccuracies that corrupt the design for several reasons: The common practice is for mechanical engineers to import optical systems into Dassault Systemes' SOLIDWORKS as STEP, IGES, or STL files, and to rely on ray bundles to provide approximations of light propagation (see Fig. Preserving the integrity of optical data when transitioning from optical to mechanical designs can pose a serious challenge for companies.

Even so, during handoff we encounter challenges in communication." The result is often delays, unnecessary design iterations and validation bottlenecks, and costly production of numerous physical prototypes to identify problems. Louis, MO), says, "As we prepare an optical design for packaging, we have mechanical engineers in mind. Robert Mentzer, optical engineer at Global Surgical Group (St. Although the toolbox for optical engineers has expanded, mechanical engineers have been left behind, without the tools to analyze and validate the impact of mechanical geometry on optical performance, evaluate optomechanical tolerances, optimize mechanical designs for multiple configurations, and/or perform structural and thermal deformation analysis. Optical and mechanical engineers frequently work in disparate design software environments using tools that lack integration. Many problems that engineers must solve are difficult to address using existing workflows and design strategies. Unfortunately, the transition between optical and mechanical design phases is costly and error-prone. Optical and mechanical engineers must work closely to turn an optical system design into a real product.

0 kommentar(er)

0 kommentar(er)